VBA Monitor

Distributed Vibration Monitoring System

The distributed architecture system, VBA Monitor, is specifically designed for the acquisition, measurement, and recording of vibration events, as well as the management of related alarms, both for industrial applications and seismic monitoring.

-

The distributed architecture system is specifically designed for the acquisition, measurement, and recording of vibration events, as well as for managing related alarms, both in industrial applications and seismic monitoring.

Based on the application objectives, the system can be equipped with the most suitable transducers for the purpose (piezoelectric or capacitive accelerometers) and signal acquisition devices with AD converters ranging from 16-bit to 24-bit, DC/AC coupling, and sampling frequencies up to 50 kS/s.

Specifically, for basic seismic monitoring applications, a configuration is typically used that includes IEPE accelerometers and distributed architecture acquisition systems equipped with 16-bit converters and anti-aliasing filters, with per-channel sampling frequencies up to 1 kS/s.

Core Functions

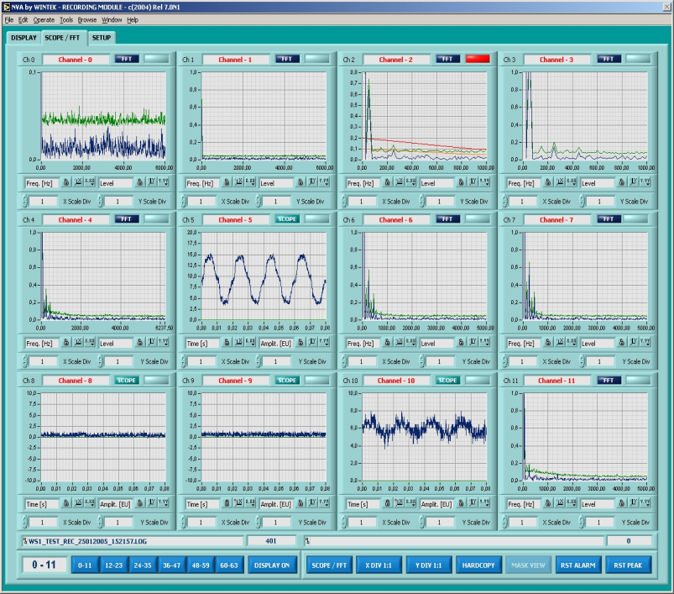

Each monitoring station can independently and in real-time perform signal acquisition, as well as analyze overall levels (optionally filtered) and FFT on signals from accelerometers (with options for single or double integration).

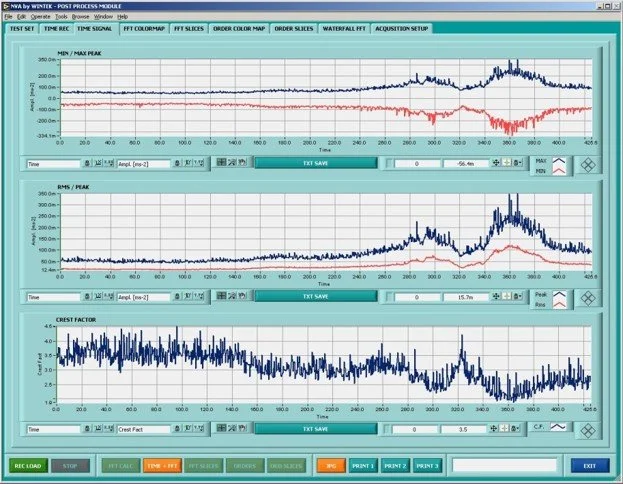

Alarm thresholds can be set for both overall levels and FFT masks. Each station can record both overall levels and spectra at user-defined intervals in convenient log files in text format. Additionally, either upon user request or in the event of an alarm threshold being exceeded, the station can also record "raw" signals from the transducers onto solid-state memory.

From the control PC, it is possible to download the data recorded on each station, enabling the user to access saved data in standard formats for in-depth analysis using specific post-processing applications.

-

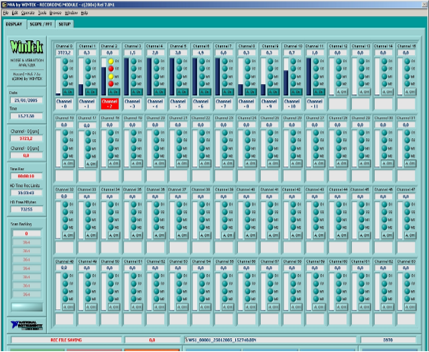

The distributed architecture system is based on signal acquisition and conditioning stations equipped with independent processing and recording capabilities for signals and events.

Each station can be connected to up to three accelerometers (up to nine in the more advanced version) and performs real-time measurements of overall values, limit checks with alarm management, and FFT analysis with spectral mask verification. Additionally, each station is equipped with internal memory and an SD card for logging and signal recording in case of alarm events.

Each station can also be connected to a supervision and control unit (typically a Windows-based personal computer) via an Ethernet network. From this unit, it is possible to monitor the operational status of each detection station, download log data, and distribute configuration files as needed.

Optionally, a digital I/O system can be installed near the supervision PC to manage alarms and operational states.

-

The distributed vibration monitoring system is ideal for various industries and scenarios, including:

1. Seismic Monitoring

Earthquake Monitoring: Real-time detection of seismic activity and alarm generation in earthquake-prone areas.

Structural Health Monitoring: Measuring vibrations in buildings, bridges, and other infrastructures to assess stability during seismic events.

Dam and Tunnel Monitoring: Ensuring the safety and operational integrity of critical structures subjected to ground movements.

2. Transportation and Civil Engineering

Railway Monitoring: Monitoring track conditions, vibrations, and the integrity of railway infrastructure.

Construction Sites: Assessing vibrations caused by construction activities to ensure compliance with safety standards and minimize environmental impact.

3. Energy Sector

Wind Turbines: Monitoring vibrations in wind turbine blades and gearboxes to optimize performance and prevent failures.

Oil & Gas: Monitoring equipment vibrations in refineries, pipelines, and offshore platforms for safety and efficiency.

Nuclear Plants: Continuous vibration monitoring of critical components such as reactors, turbines, and cooling systems to ensure operational safety and prevent catastrophic failures.

4. Environmental and Geophysical Studies

Geotechnical Monitoring: Real-time data collection for landslide prediction and soil stability analysis.

Volcanology: Monitoring vibrations caused by volcanic activity to enhance early warning systems and disaster preparedness.

The system's modular and flexible design ensures it meets the specific needs of these diverse applications.

-

Supervision System

PC Control Room

Processor: Intel-based

Operating System: Windows 10/11

Local Network: Ethernet 100/1000

Acquisition Systems

Model: VBA-Mon-HW3

AD Converters: 16-bit + Anti-alias Filter – Up to 3 channels

Input Range: From ±1 V to ±5 V

Sampling Rate: Up to 5 kS/s per channel

Transducer Power Supply: IEPE (24 VDC - 4 mA)

Power Supply: 24 VDC – Max 60 W

Connectivity: Ethernet 100/1000, RS232, CAN, USB, SD Card

Storage: Up to 2 GB on SD Card

Protection Rating: IP65

Operating Temperature: -20/+50 °C (optional extended range available)

Software Applications and Features

Channel Setup

Sensitivity

Filters

Limits (Max/Min)

Integration

Analysis

Time Analysis (Overall – Max and Min)

FFT Analysis

Logging

Measurement Logs: Event-based or Manual Mode

Alarms

Alarm Configurations and AND/OR Tables

Users

User Mode: View and Log access

Admin Mode: Channel and Limit Configuration

VBA MONITOR - Architecture Diagram